On January 22, 2026, the Hyundai Motor Company Labor Union officially announced its strong opposition to deploying the humanoid robot “Atlas,” a physical AI system developed by Hyundai Motor Group, into production sites. The union stated that “not a single robot will be allowed onto the shop floor without labor–management agreement,” warning that the introduction of Atlas could lead to labor cost reduction and workforce downsizing, ultimately causing a serious employment shock.

So what exactly is the robot Atlas that they are opposing?

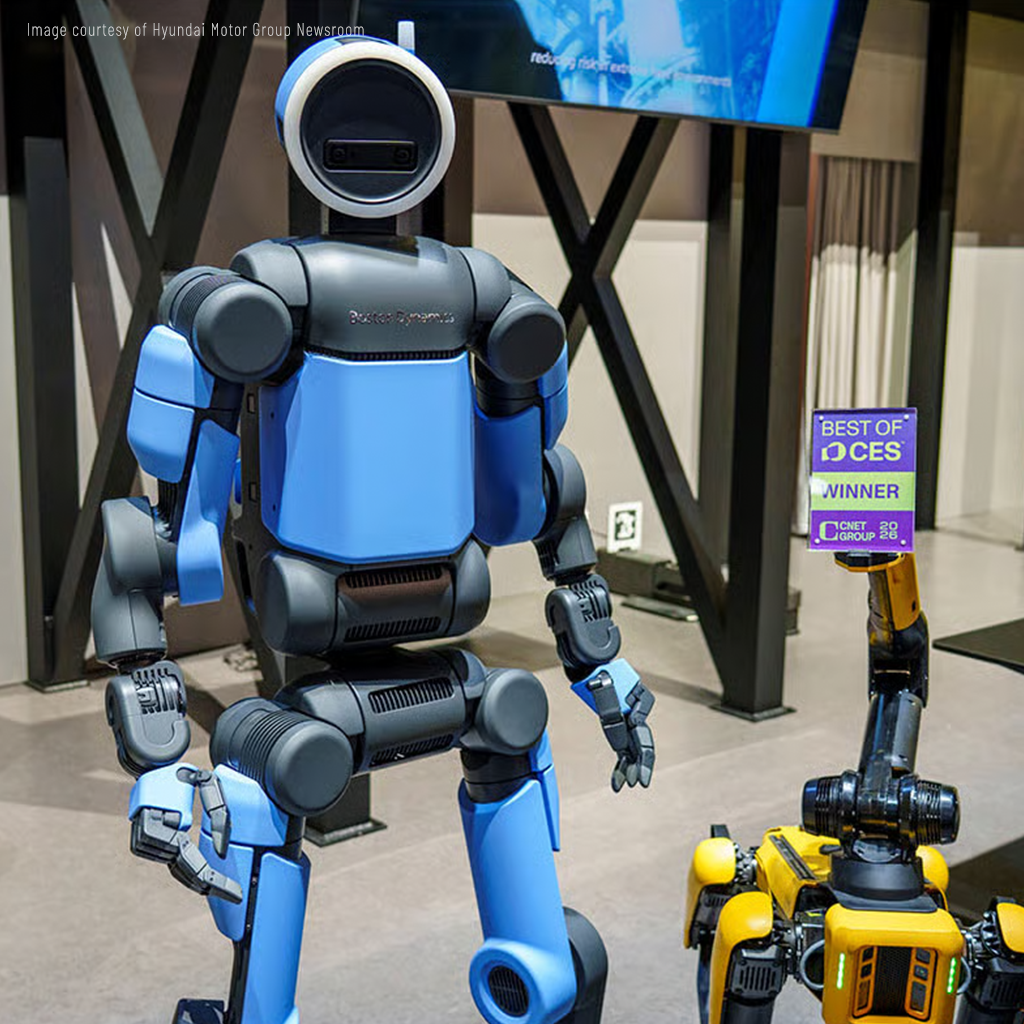

Atlas is a humanoid robot developed by the U.S. robotics company Boston Dynamics. First unveiled in 2013, Atlas has gone through multiple generations of development, with its latest model revealed at CES (Consumer Electronics Show) 2026.

Atlas has a round, circular face and a body comparable in size to an adult human, standing approximately 1.9 meters tall and weighing about 90 kilograms. It is capable of lifting up to 50 kilograms and performing fluid rotations and body twists that go well beyond what the human body can physically sustain. Atlas can operate continuously for about four hours on battery power, and when the battery is depleted, it autonomously moves to a charging station to recharge. It can work without difficulty in temperatures as low as –20°C and as high as 40°C.

The arrival of Atlas left many observers deeply unsettled.

Atlas is no longer a laboratory toy. It is a humanoid robot ready for real factory deployment. Observers described Atlas as “the most realistic humanoid” and “the best robot at CES,” and it received the “Best Robot” award from the CNET Group—recognition that reflected how far industrial robotics has advanced.

Boston Dynamics, the company behind Atlas, was founded in 1992 and is one of the most prominent robotics developers in the United States, known for creating dynamic robots such as BigDog, Spot, and Atlas. In 2021, Hyundai Motor Group acquired an 80% stake in Boston Dynamics. Through this acquisition, Hyundai declared its shift from a conventional automobile manufacturer to a robotics and physical AI company, presenting its robot strategy—including plans for mass production of Atlas—as a central pillar of its long-term industrial vision.

The annual operating cost of a single Atlas unit is estimated at approximately 14 million won. This is only about 10% of the average annual labor cost of a Hyundai employee, which stands at roughly 140 million won. When compared with the approximately 420 million won required annually to employ human workers on a three-shift basis, Atlas operates at roughly 3.3% of that cost.

For this reason, the Hyundai Motor labor union has strongly opposed robot adoption driven by labor cost reduction, arguing that such a move would directly lead to job losses. The union has also warned that automation robots like Atlas could weaken Korea’s domestic production base and accelerate overseas relocation. In reality, production volumes at Korean plants have been steadily declining, while Hyundai has built the Metaplant America facility in Georgia, with plans to continue increasing its share of production. Hyundai Motor Group maintains that it intends to minimize disruption by introducing robots gradually, in line with natural workforce reductions caused by aging and retirement.

At this point, it is impossible not to raise a question.

The reason Hyundai Motor Group accommodated the labor union’s demands in the past was simple: it needed their labor. Despite countless confrontations, both sides ultimately compromised and negotiated because that labor was indispensable. But if that labor is no longer necessary, the justification for accepting those demands disappears as well. Companies would no longer need to wrestle with labor disputes, human rights issues, working-hour regulations, industrial accidents, or compensation claims.

If you were the CEO of a company, which would you choose: a situation where you invest 300 million won and still shoulder endless responsibilities, or one where you invest roughly 14 million won a year and bear virtually none?

Is this really even a dilemma?

For generations, humans provided labor, received wages in return, used that income to buy food, build families, and raise children. Now, physical AI systems far more capable than humans are beginning to replace human labor at a fraction of the cost. Humans are gradually being pushed out of the workplace, unable to work, and inevitably cut off from wages.

What once existed only in science fiction is becoming a visible reality.

Can this be stopped?

Recently, I needed to purchase a new smartphone for my elderly parents. Instead of an expensive iPhone or Galaxy device, I looked into Xiaomi phones. While iPhones easily exceed 2 million won, Xiaomi phones cost only about 200,000 won. Curious about this drastic price difference, I looked deeper—and discovered that there was not a single human worker in Xiaomi’s production factory. Smartphones were being manufactured in a facility where machines operated nonstop, 24 hours a day. From the outset, the production cost structure made competition impossible.

The factory did not even need lights—it was dark.

It was a shocking sight.

Now automobiles, and indeed all industries, are moving down the same path. The technological capabilities of Hyundai Motor Group’s humanoid robot Atlas are undeniably astonishing.

And that is precisely why it is impossible to simply applaud.

If humans lose the right to labor—if they are no longer able to work—how are they supposed to survive?

Concepts such as AI basic income and universal high income are being proposed as solutions to humanity’s future livelihood. But will they truly be realized? If AI is trained on data derived from humanity, would AI corporations genuinely agree that the wealth generated by AI should be shared equally by all?

Since the agricultural revolution, there has never been a time when human labor became unnecessary. We have no idea what kind of world awaits us next. Some claim that old jobs will disappear and new ones will emerge—but is that vision really so optimistic?

Even if people shout, “Not a single robot must be allowed in,” the arrival of robots cannot ultimately be stopped. Everyone knows this. The Hyundai Motor labor union knows it too.

It is frightening.

How, then, are humans supposed to survive?

Tonight, sleep does not come easily.

Oh—robots do not need sleep at all.

—

By Sunjae Park

Editor, Korea Insight Weekly

Leave a Reply